Asbestos is a mineral fiber that can be positively identified only with a special type of microscope. There are several types of asbestos fibers. In the past, asbestos was added to a variety of products to strengthen them and to provide heat insulation and fire resistance. InterNACHI inspectors can supplement their knowledge with the information offered in this guide.

How Can Asbestos Affect Human Health?

From studies of people who were exposed to asbestos in factories and shipyards, we know that breathing high levels of asbestos fibers can lead to an increased risk of lung cancer in the forms of mesothelioma, which is a cancer of the lining of the chest and the abdominal cavity, and asbestosis, in which the lungs become scarred with fibrous tissue.

The risk of lung cancer and mesothelioma increase with the number of fibers inhaled. The risk of lung cancer from inhaling asbestos fibers is also greater if you smoke. People who get asbestosis have usually been exposed to high levels of asbestos for a long time. The symptoms of these diseases do not usually appear until about 20 to 30 years after the first exposure to asbestos.

Most people exposed to small amounts of asbestos, as we all are in our daily lives, do not develop these health problems. However, if disturbed, asbestos material may release asbestos fibers, which can be inhaled into the lungs. The fibers can remain there for a long time, increasing the risk of disease. Asbestos material that would crumble easily if handled, or that has been sawed, scraped, or sanded into a powder, is more likely to create a health hazard.

Where Would Asbestos Be Found, and When Can it Be a Problem?

Most products made today do not contain asbestos. Those few products made which still contain asbestos that could be inhaled are required to be labeled as such. However, until the 1970s, many types of building products and insulation materials used in homes contained asbestos.

Common products that might have contained asbestos in the past, and conditions which may release fibers, include:

-

steam pipes, boilers and furnace ducts insulated with an asbestos blanket or asbestos paper tape. These materials may release asbestos fibers if damaged, repaired, or removed improperly;

-

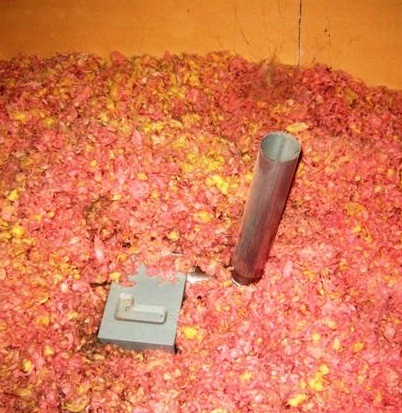

resilient floor tiles (vinyl asbestos, asphalt and rubber), the backing on vinyl sheet flooring, and adhesives used for installing floor tile. Sanding tiles can release fibers, and so may scraping or sanding the backing of sheet flooring during removal;

-

cement sheet, millboard and paper used as insulation around furnaces and wood-burning stoves. Repairing or removing appliances may release asbestos fibers, and so may cutting, tearing, sanding, drilling, or sawing insulation;

-

door gaskets in furnaces, wood stoves and coal stoves. Worn seals can release asbestos fibers during use;

-

soundproofing or decorative material sprayed on walls and ceilings. Loose, crumbly or water-damaged material may release fibers, and so will sanding, drilling or scraping the material;

-

patching and joint compounds for walls and ceilings, and textured paints. Sanding, scraping, or drilling these surfaces may release asbestos fibers;

-

asbestos cement roofing, shingles and siding. These products are not likely to release asbestos fibers unless sawed, dilled or cut;

-

artificial ashes and embers sold for use in gas-fired fireplaces, and other older household products, such as fireproof gloves, stove-top pads, ironing board covers and certain hairdryers; and

-

automobile brake pads and linings, clutch facings and gaskets.

Where Asbestos Hazards May Be Found in a Home

- Some roofing and siding shingles are made of asbestos cement.

- Houses built between 1930 and 1950 may have asbestos as insulation.

- Asbestos may be present in textured paint and in patching compounds used on wall and ceiling joints. Their use was banned in 1977.

- Artificial ashes and embers sold for use in gas-fired fireplaces may contain asbestos.

- Older products, such as stove-top pads, may have some asbestos compounds.

- Walls and floors around wood-burning stoves may be protected with asbestos paper, millboard or cement sheets.

- Asbestos is found in some vinyl floor tiles and the backing on vinyl sheet flooring and adhesives.

- Hot water and steam pipes in older houses may be coated with an asbestos material or covered with an asbestos blanket or tape.

- Oil and coal furnaces and door gaskets may have asbestos insulation.

What Should Be Done About Asbestos in the Home?

If you think asbestos may be in your home, don’t panic. Usually, the best thing to do is to leave asbestos material that is in good condition alone. Generally, material in good condition will not release asbestos fibers. There is no danger unless the asbestos is disturbed and fibers are released and then inhaled into the lungs. Check material regularly if you suspect it may contain asbestos. Don’t touch it, but look for signs of wear or damage, such as tears, abrasions or water damage. Damaged material may release asbestos fibers. This is particularly true if you often disturb it by hitting, rubbing or handling it, or if it is exposed to extreme vibration or air flow. Sometimes, the best way to deal with slightly damaged material is to limit access to the area and not touch or disturb it. Discard damaged or worn asbestos gloves, stove-top pads and ironing board covers. Check with local health, environmental or other appropriate agencies to find out proper handling and disposal procedures. If asbestos material is more than slightly damaged, or if you are going to make changes in your home that might disturb it, repair or removal by a professional is needed. Before you have your house remodeled, find out whether asbestos materials are present.

How to Identify Materials That Contain Asbestos

You can’t tell whether a material contains asbestos simply by looking at it, unless it is labeled. If in doubt, treat the material as if it contains asbestos, or have it sampled and analyzed by a qualified professional. A professional should take samples for analysis, since a professional knows what to look for, and because there may be an increased health risk if fibers are released. In fact, if done incorrectly, sampling can be more hazardous than leaving the material alone. Taking samples yourself is not recommended. If you nevertheless choose to take the samples yourself, take care not to release asbestos fibers into the air or onto yourself. Material that is in good condition and will not be disturbed (by remodeling, for example) should be left alone. Only material that is damaged or will be disturbed should be sampled.

Anyone who samples asbestos-containing materials should have as much information as possible on the handling of asbestos before sampling and, at a minimum, should observe the following procedures:

-

Make sure no one else is in the room when sampling is done.

-

Wear disposable gloves or wash hands after sampling.

-

Shut down any heating or cooling systems to minimize the spread of any released fibers.

-

Do not disturb the material any more than is needed to take a small sample.

-

Place a plastic sheet on the floor below the area to be sampled.

-

Wet the material using a fine mist of water containing a few drops of detergent before taking the sample. The water/detergent mist will reduce the release of asbestos fibers.

-

Carefully cut a piece from the entire depth of the material using a small knife, corer or other sharp object. Place the small piece into a clean container (a 35-mm film canister, small glass or plastic vial, or high-quality resealable plastic bag).

-

Tightly seal the container after the sample is in it.

-

Carefully dispose of the plastic sheet. Use a damp paper towel to clean up any material on the outside of the container or around the area sampled. Dispose of asbestos materials according to state and local procedures.

-

Label the container with an identification number and clearly state when and where the sample was taken.

-

Patch the sampled area with the smallest possible piece of duct tape to prevent fiber release.

-

Send the sample to an asbestos analysis laboratory accredited by the National Voluntary Laboratory Accreditation Program (NVLAP) at the National Institute of Standards and Technology (NIST). Your state or local health department may also be able to help.

How to Manage an Asbestos Problem

If the asbestos material is in good shape and will not be disturbed, do nothing! If it is a problem, there are two types of corrections: repair and removal. Repair usually involves either sealing or covering asbestos material. Sealing (encapsulation) involves treating the material with a sealant that either binds the asbestos fibers together or coats the material so that fibers are not released. Pipe, furnace and boiler insulation can sometimes be repaired this way. This should be done only by a professional trained to handle asbestos safely. Covering (enclosure) involves placing something over or around the material that contains asbestos to prevent the release of fibers. Exposed insulated piping may be covered with a protective wrap or jacket. With any type of repair, the asbestos remains in place. Repair is usually cheaper than removal, but it may make removal of asbestos later (if found to be necessary) more difficult and costly. Repairs can either be major or minor. Major repairs must be done only by a professional trained in methods for safely handling asbestos. Minor repairs should also be done by professionals, since there is always a risk of exposure to fibers when asbestos is disturbed.

Repairs

Doing minor repairs yourself is not recommended, since improper handling of asbestos materials can create a hazard where none existed. If you nevertheless choose to do minor repairs, you should have as much information as possible on the handling of asbestos before doing anything. Contact your state or local health department or regional EPA office for information about asbestos training programs in your area. Your local school district may also have information about asbestos professionals and training programs for school buildings. Even if you have completed a training program, do not try anything more than minor repairs. Before undertaking minor repairs, carefully examine the area around the damage to make sure it is stable. As a general rule, any damaged area which is bigger than the size of your hand is not considered a minor repair.

Before undertaking minor repairs, be sure to follow all the precautions described previously for sampling asbestos material. Always wet the asbestos material using a fine mist of water containing a few drops of detergent. Commercial products designed to fill holes and seal damaged areas are available. Small areas of material, such as pipe insulation, can be covered by wrapping a special fabric, such as re-wettable glass cloth, around it. These products are available from stores (listed in the telephone directory under “Safety Equipment and Clothing”) which specialize in asbestos materials and safety items.

Removal is usually the most expensive method and, unless required by state or local regulations, should be the last option considered in most situations. This is because removal poses the greatest risk of fiber release. However, removal may be required when remodeling or making major changes to your home that will disturb asbestos material. Also, removal may be called for if asbestos material is damaged extensively and cannot be otherwise repaired. Removal is complex and must be done only by a contractor with special training. Improper removal may actually increase the health risks to you and your family.

Asbestos Professionals: Who Are They and What Can They Do?

Asbestos professionals are trained in handling asbestos material. The type of professional will depend on the type of product and what needs to be done to correct the problem. You may hire a general asbestos contractor or, in some cases, a professional trained to handle specific products containing asbestos.

Asbestos professionals can conduct inspections, take samples of suspected material, assess its condition, and advise on the corrections that are needed, as well as who is qualified to make these corrections. Once again, material in good condition need not be sampled unless it is likely to be disturbed. Professional correction or abatement contractors repair and remove asbestos materials.

Some firms offer combinations of testing, assessment and correction. A professional hired to assess the need for corrective action should not be connected with an asbestos-correction firm. It is better to use two different firms so that there is no conflict of interest. Services vary from one area to another around the country.

The federal government offers training courses for asbestos professionals around the country. Some state and local governments also offer or require training or certification courses. Ask asbestos professionals to document their completion of federal or state-approved training. Each person performing work in your home should provide proof of training and licensing in asbestos work, such as completion of EPA-approved training. State and local health departments or EPA regional offices may have listings of licensed professionals in your area.

If you have a problem that requires the services of asbestos professionals, check their credentials carefully. Hire professionals who are trained, experienced, reputable and accredited — especially if accreditation is required by state or local laws. Before hiring a professional, ask for references from previous clients. Find out if they were satisfied. Ask whether the professional has handled similar situations. Get cost estimates from several professionals, as the charges for these services can vary.

Though private homes are usually not covered by the asbestos regulations that apply to schools and public buildings, professionals should still use procedures described in federal or state-approved training. Homeowners should be alert to the chance of misleading claims by asbestos consultants and contractors. There have been reports of firms incorrectly claiming that asbestos materials in homes must be replaced. In other cases, firms have encouraged unnecessary removal or performed it improperly. Unnecessary removal is a waste of money. Improper removal may actually increase the health risks to you and your family. To guard against this, know what services are available and what procedures and precautions are needed to do the job properly.

In addition to general asbestos contractors, you may select a roofing, flooring or plumbing contractor trained to handle asbestos when it is necessary to remove and replace roofing, flooring, siding or asbestos-cement pipe that is part of a water system. Normally, roofing and flooring contractors are exempt from state and local licensing requirements because they do not perform any other asbestos-correction work.

Asbestos-containing automobile brake pads and linings, clutch facings and gaskets should be repaired and replaced only by a professional using special protective equipment. Many of these products are now available without asbestos.

If you hire an InterNACHI® inspector who is trained in asbestos inspection:

-

Make sure that the inspection will include a complete visual examination, and the careful collection and lab analysis of samples. If asbestos is present, the inspector should provide a written evaluation describing its location and extent of damage, and give recommendations for correction or prevention.

-

Make sure an inspecting firm makes frequent site visits if it is hired to assure that a contractor follows proper procedures and requirements. The inspector may recommend and perform checks after the correction to assure that the area has been properly cleaned.

If you hire a corrective-action contractor:

-

Check with your local air pollution control board, the local agency responsible for worker safety, and the Better Business Bureau. Ask if the firm has had any safety violations. Find out if there are legal actions filed against it.

-

Insist that the contractor use the proper equipment to do the job. The workers must wear approved respirators, gloves and other protective clothing.

-

Before work begins, get a written contract specifying the work plan, cleanup, and the applicable federal, state and local regulations which the contractor must follow (such as notification requirements and asbestos disposal procedures). Contact your state and local health departments, EPA regional office, and the Occupational Safety and Health Administration’s regional office to find out what the regulations are. Be sure the contractor follows local asbestos removal and disposal laws. At the end of the job, get written assurance from the contractor that all procedures have been followed.

-

Assure that the contractor avoids spreading or tracking asbestos dust into other areas of your home. They should seal off the work area from the rest of the house using plastic sheeting and duct tape, and also turn off the heating and air conditioning system. For some repairs, such as pipe insulation removal, plastic bags may be adequate. They must be sealed with tape and properly disposed of when the job is complete.

-

Make sure the work site is clearly marked as a hazardous area. Do not allow household members or pets into the area until work is completed.

-

Insist that the contractor apply a wetting agent to the asbestos material with a hand sprayer that creates a fine mist before removal. Wet fibers do not float in the air as easily as dry fibers and will be easier to clean up.

-

Make sure the contractor does not break removed material into smaller pieces. This could release asbestos fibers into the air. Pipe insulation was usually installed in pre-formed blocks and should be removed in complete pieces.

-

Upon completion, assure that the contractor cleans the area well with wet mops, wet rags, sponges and/or HEPA (high-efficiency particulate air) vacuum cleaners. A regular vacuum cleaner must never be used. Wetting helps reduce the chance of spreading asbestos fibers in the air. All asbestos materials and disposable equipment and clothing used in the job must be placed in sealed, leakproof, and labeled plastic bags. The work site should be visually free of dust and debris. Air monitoring (to make sure there is no increase of asbestos fibers in the air) may be necessary to assure that the contractor’s job is done properly. This should be done by someone not connected with the contractor.

Do not dust, sweep or vacuum debris that may contain asbestos. These actions will disturb tiny asbestos fibers and may release them into the air. Remove dust by wet-mopping or with a special HEPA vacuum cleaner used by trained asbestos contractors. https://www.nachi.org/asbestos.htm

For information on mesothelioma go to https://www.pleuralmesothelioma.com/cancer/types/.

More information is available from Mesothelioma Cancer Network.

For more information go to Exposure to Asbestos.

Red Horse Home Inspection LLC is proud to service the Black Hills of South Dakota. If you are buying or selling a home in the Black Hills or the surrounding area please schedule your inspection online.

Follow us on Facebook and Instagram.

Efflorescence is the white chalky powder that you might find on the surface of a concrete or brick wall. It can be a cosmetic issue, or it can be an indication of moisture intrusion that could lead to major structural and indoor air quality issues. A home inspector should understand what efflorescence is in order to recognize potential moisture problems.

Efflorescence is the white chalky powder that you might find on the surface of a concrete or brick wall. It can be a cosmetic issue, or it can be an indication of moisture intrusion that could lead to major structural and indoor air quality issues. A home inspector should understand what efflorescence is in order to recognize potential moisture problems.

.

.

your recessed lighting. Don’t run your bathroom and kitchen vents into the attic, they should be direct vented to the outside of your home. Your attic should be well ventilated to remove any heat and moisture out of the attic space. Seal all penetrations that pass into the attic. Finally, if the duct work is in the attic space, it should be sealed and insulated to prevent heat loss into the attic. Taking these steps will prevent ice dams form forming on your roof.

your recessed lighting. Don’t run your bathroom and kitchen vents into the attic, they should be direct vented to the outside of your home. Your attic should be well ventilated to remove any heat and moisture out of the attic space. Seal all penetrations that pass into the attic. Finally, if the duct work is in the attic space, it should be sealed and insulated to prevent heat loss into the attic. Taking these steps will prevent ice dams form forming on your roof. ent grade need to have a guardrail. The guardrail should be not less than 36 inches high and have intermediate rails that will not let a 4 inch sphere pass between them. The stair riser heights should be uniform with no more than 3/8th of an inch difference between rises. The rise should be no more 7 3/4″ and no less than 4″ and the run should be no less that 10″.

ent grade need to have a guardrail. The guardrail should be not less than 36 inches high and have intermediate rails that will not let a 4 inch sphere pass between them. The stair riser heights should be uniform with no more than 3/8th of an inch difference between rises. The rise should be no more 7 3/4″ and no less than 4″ and the run should be no less that 10″.